FOCUS ON SAFETY:

New Technology Used in Helmets at Point Thomson Allows for Greater Worker Safety

Alaska Oil & Gas Association / January 2015

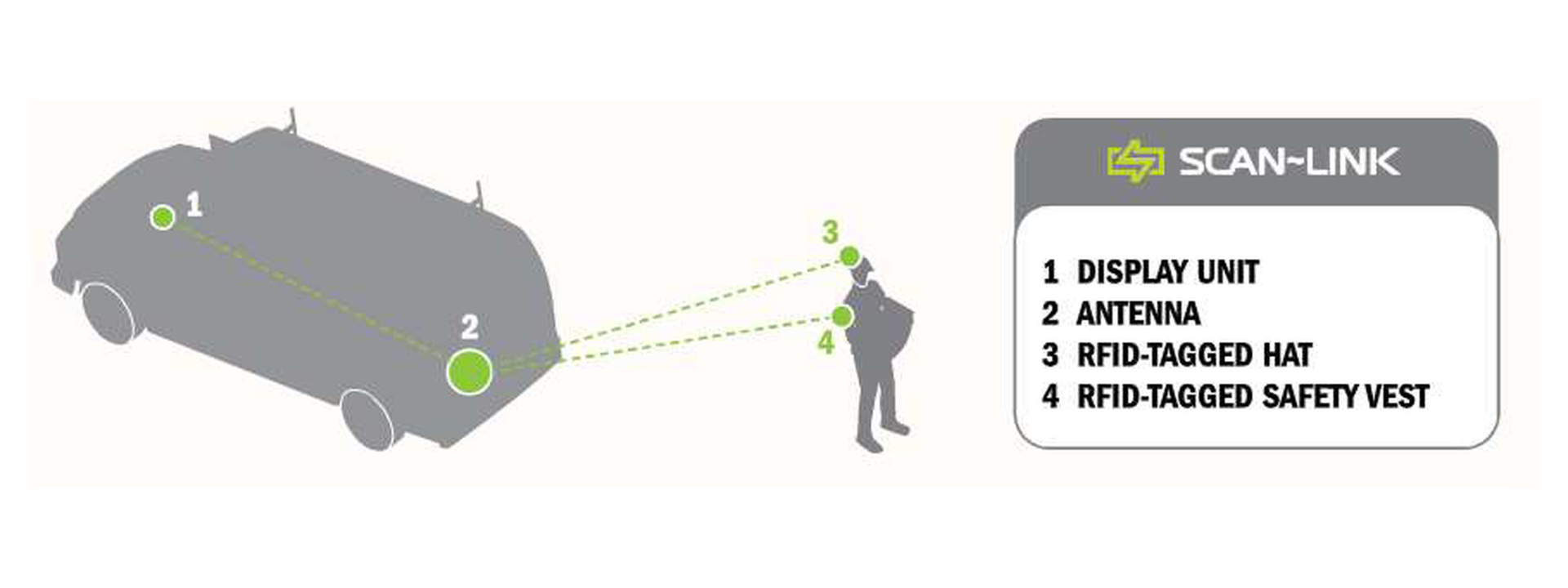

At Point Thomson, worker safety is the highest priority. Since March 2013, ExxonMobil has installed the SCAN~LINK Radio Frequency Identification System, or RFID, in every worker's helmet issued by the project to help protect them from moving equipment.

The system works with special SCAN~LINK tags that are placed in the helmet and antennas that are mounted on the back exterior of equipment. As a ground worker moves within 15-20 feet of a vehicle equipped with the system, a monitor that displays the nearby ground worker and an alarm sounds in the vehicle's cab. Together, these alert the operator of a ground worker who is nearby. The system is another level of safety for workers, particularly in the blind spots of equipment and North Slope low-visibility conditions.

Point Thomson is the first to use this SCAN~LINK technology on the North Slope. ExxonMobil is proud to continue to bring innovative technology to Point Thomson—the forefront of Alaska's new era of natural gas development.

Point Thomson is a natural has and condensate field located 60 miles east of Prudhoe Bay on the North Slope of Alaska. The Point Thomson reservoir holds an estimated 8 trillion cubic feet of natural gas and 200 million barrels of natural gas condensate, a high-quality hydrocarbon similar to kerosene or diesel. The Point Thomson gas resources represent about 25 percent of known gas resources on the North Slope. Exxon Mobil is developing initial facilities with the capacity to produce up to 10,000 barrels per day of natural gas condensate.

SCAN~LINK technology at work on the North Slope.