Utilizing RFID for worker detection in all areas of your sites, specifically engineered for the rigorous demands of aggregate environments.

AGGREGATE & MINING SAFETY SOLUTIONS

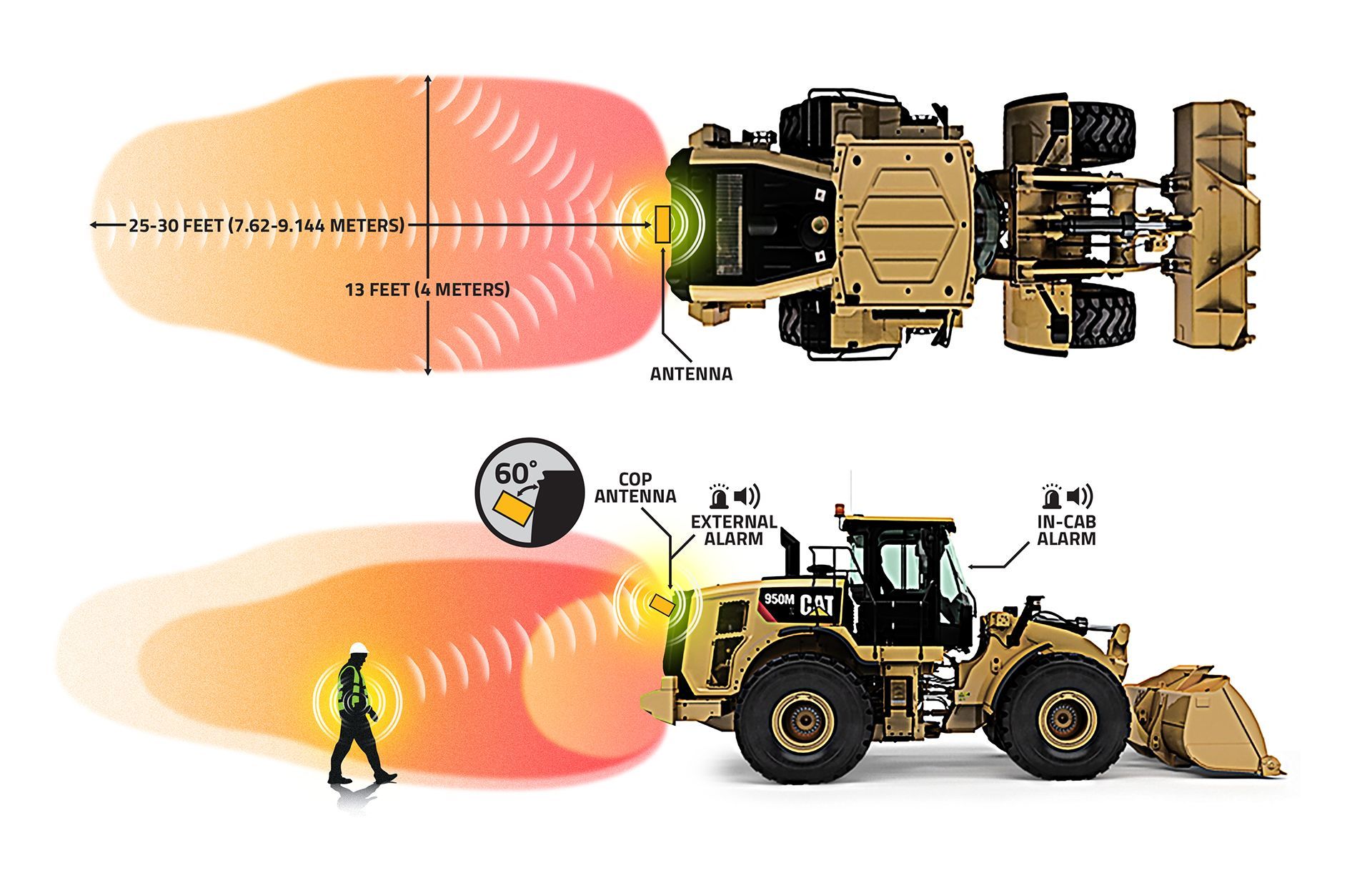

SCAN~LINK RFID Detection for Real-Time Worker Safety

See how SCAN~LINK’s passive RFID detection system monitors personnel around heavy equipment, instantly signaling operators and stopping loaders or conveyors to prevent accidents and protect workers.

We're Here to Support Your Safety Goals

Contact us to learn how SCAN~LINK’s passive RFID safety solutions improve safety and compliance, or request pricing and a detailed quote tailored to your jobsite.

Contact Us

Contact Us

13 Windward Dr.

Unit 204

Grimsby, Ontario

L3M 4E8

T: 1-905-304-6100

Toll Free: 1-866-554-5582

info@scan-link.com