5 Signs Your Jobsite Has a Visibility Problem

How to Identify Hidden Hazards Before They Lead to Disaster

TL;DR

If your jobsite has frequent close calls, large blind spots, reliance on hand signals, ignored backup alarms, or shutdowns due to visibility concerns, your jobsite has a visibility problem. These issues are leading causes of struck-by injuries and fatalities. Fortunately, proven RFID proximity detection technology can eliminate these risks by making the invisible visible.

Table of Contents

- Why Visibility Matters

- 5 Signs Your Site Has a Visibility Problem

- Safety Solutions: How to Improve Visibility

- RFID Technology: Making the Invisible Visible

Why Visibility Matters

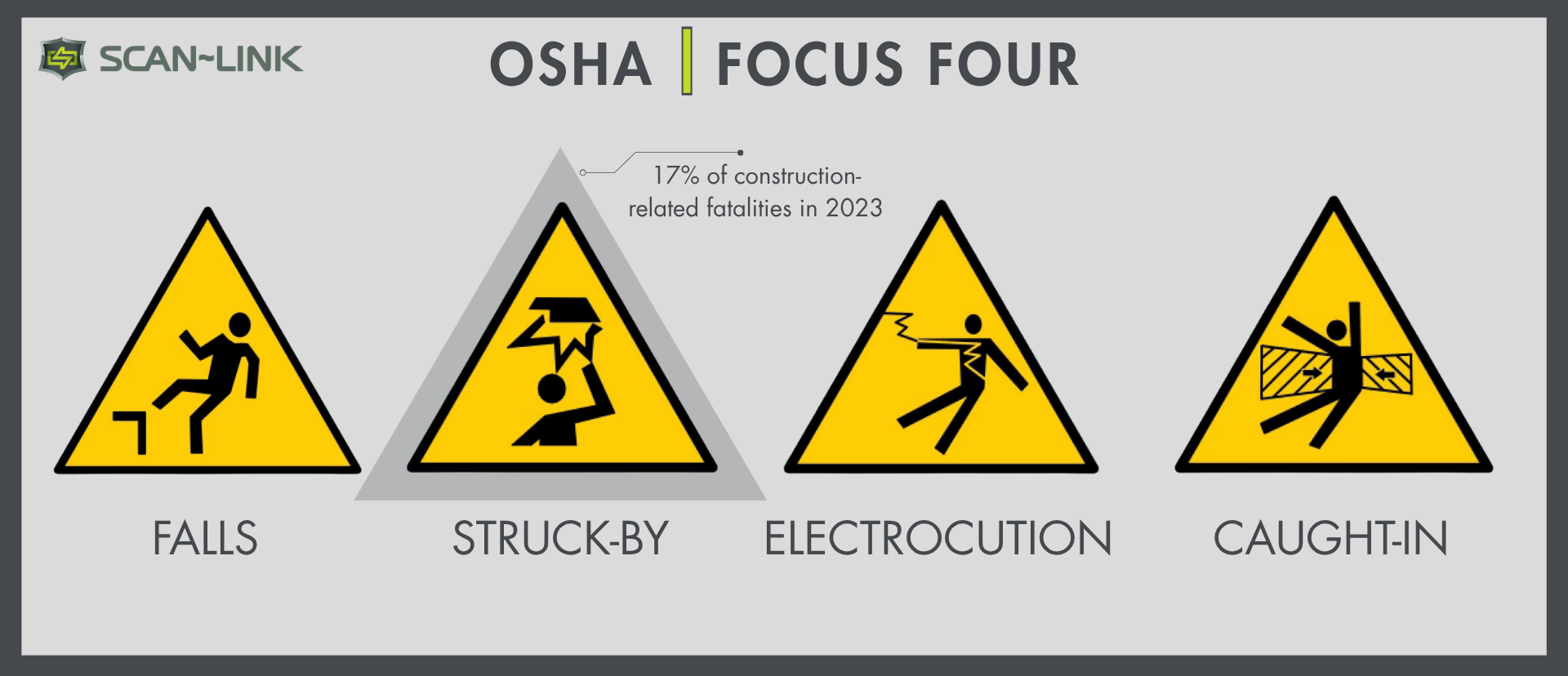

Struck-by incidents represent 17% of all construction-related fatalities according to Procore’s 2023 safety data, securing their position as one of OSHA’s “Focus Four” deadly hazards.

Even in well-managed industrial sites, construction site blind spots and limited operator visibility continue to cause preventable accidents, especially around mobile equipment. When the difference between life and death can be just a few feet, “close enough” isn’t good enough.

OSHA's "Focus Four"

5 Signs Your Site Has a Visibility Problem

- Frequent "Close Call" Incidents

When team members regularly report statements like:

- "That was close"

- "I didn't see them coming"

- "I hit the brakes just in time"

These aren't isolated incidents, they're inadequate detection capabilities and visibility gaps. Each near-miss represents a failure in your safety infrastructure that could easily escalate to a fatality.

These incidents indicate systematic failures in detection capabilities that traditional safety measures may not address adequately.

2. Your Equipment has Significant Blind Spots

Heavy machinery including haul trucks, loaders, and excavators inherently contain areas invisible to operators, even with mirrors and camera systems. These blind spots become exponentially more dangerous when pedestrian workers operate in close proximity to mobile equipment.

Conducting comprehensive visibility audits for each vehicle type can help identify these limitations and inform decisions about additional safety measures.

3. Over-Reliance on Manual Communication Systems

While spotters, hand signals, and radio communications serve important functions, they remain vulnerable to human error, environmental interference, and fatigue-related failures. Sites depending exclusively on human vigilance operate with inherent risk factors.

4. Beepers and Lights Are Being Ignored

Reverse beepers and warning lights, while standard equipment, often become background noise in high-activity environments such as construction sites, sawmills, and waste management facilities. When ground personnel no longer register these alerts as urgent warnings, their protective value disappears entirely.

Environmental Factors Affecting Warning Systems:

- High noise levels from multiple equipment operations

- Competing audio signals and alarms

- Worker hearing protection reducing alarm effectiveness

- Visual warning systems blocked by weather or debris

5. You Don’t Have a Personnel Detection System in Place

Operating construction sites without technological detection solutions leaves safety protocols fundamentally incomplete. Always complete a pre-job risk assessment and ensure all mobile equipment has working backup alarms, but automated systems provide additional protection layers that manual protocols cannot match.

Without automated personnel detection technology, construction sites accept unnecessary risks that proven proximity warning systems can eliminate effectively.

Safety Solutions: How to Improve Visibility

Improving construction site safety doesn’t always mean replacing equipment or adding more staff. Instead, focus on strategic improvements that make the most impact.

Comprehensive Risk Assessment:

- Identify blind spots on all mobile equipment

- Track and analyze near-miss incidents

- Provide regular struck-by prevention training and certifications

- Conduct visibility audits and hazard mapping

Technology Integration:

- Go beyond cameras and alarms with intelligent detection systems

- Use RFID proximity detection to supplement human oversight

- Implement real-time safety alerts for both operators and workers

- Connect detection technology with existing safety management systems

Best Practices for Construction Site Visibility:

- Separate vehicle and pedestrian traffic areas

- Require high-visibility clothing for all personnel

- Assign signalers in high-risk material handling zones

- Enforce clear safety protocols in equipment operation areas

RFID Technology: Making the Invisible Visible

Advanced personnel detection systems utilize RFID tags seamlessly integrated into standard construction safety equipment, such as hard hats and high-visibility safety vests. Vehicle-mounted RFID Antennas automatically detect these tags, creating protective proximity zones around mobile construction equipment.

How it Works on the Jobsite:

- Operators receive instant visual and audio alerts when workers enter equipment danger zones.

- Ground personnel hear external alarms, ensuring immediate awareness.

- Every detection event is logged with timestamps and worker ID.

- Safety managers gain access to detailed reports for compliance and performance analysis.

RFID Construction Safety Technology Benefits:

- Immediate hazard detection regardless of visibility conditions or weather

- Comprehensive event logging for safety analysis and OSHA compliance

- Reduced downtime by preventing accidents before they occur.

- Lower insurance costs through measurable risk reduction.

- Stronger safety reputation, giving contractors a competitive edge in bidding.

This detection technology is currently protecting construction workers on jobsites throughout North America and other parts of the world, delivering measurable safety improvements and operational benefits for construction companies, general contractors, and heavy equipment operators.

Real-World Construction Safety Applications:

- Highway construction and roadwork zones

- Commercial building construction sites

- Industrial facility maintenance and operations

- Mining and quarry operations

- Waste management and recycling facilities

- Port and shipping terminal operations

Eliminate Construction Site Visibility Risks Today

Construction equipment visibility failures don't have to be inevitable workplace hazards. SCAN~LINK's RFID proximity detection systems provide the technological foundation for preventing struck-by incidents, reducing construction site accidents, and establishing your organization as an industry safety leader.

Professional construction safety managers trust SCAN~LINK's proven proximity warning systems to protect workers around mobile equipment and eliminate dangerous blind spots that traditional safety measures cannot address.

Ready to improve your construction site safety? Contact SCAN~LINK's proximity detection specialists to conduct a comprehensive visibility assessment and discover how advanced RFID technology can transform your construction safety performance.

When construction site visibility fails, RFID proximity detection delivers proven protection.

One Incident Can Cost You Everything

Jobsite shutdowns from accidents lead to costly delays, legal issues, and downtime. With SCAN~LINK’s free self-assessment safety checklist, you’ll quickly identify blind spots, reduce risks, and strengthen compliance on your site.

Strengthen Your Safety with our

Free Safety Checklist

Take safety into your own hands with our free self-assessment safety checklist. Our checklist will help you assess your own jobsite and discover potential blind spots and hazards.