SCAN~LINK: Leading the Future of Workplace Safety with RFID Technology

“I skate to where the puck is going to be, not to where it has been” – Wayne Gretzky

SCAN~LINK Technologies Inc. is a Canadian owned and operated company that manufactures and distributes Radio Frequency Identification (RFID) based Safety Solutions. Established in 2009, the founders Uwe Schaible, Ph.D. P. Eng. and Jonathan Fava were on a mission to be the leaders in RFID Safety. Between Jonathan’s 18+ years in the Safety Industry and Uwe’s 10+ years as an Engineer with an RFID background, the Amour system was created. It was obvious to them that the current safety systems were not sufficient; they needed to be where the safety industry was going.

The SCAN~LINK Armour System™ is an RFID-based personnel detection system that detects people rather than objects behind mobile equipment. The ground workers are tagged with passive RFID tags in their vest and hard hat, and the mobile equipment is outfitted with an antenna/reader. When a worker wearing the tagged apparel walks behind a machine, the operator is alerted with an audio and visual prompt letting them know that there is a person behind the machine, as opposed to a random object. Additionally, upon detection, an external alarm is activated alerting the ground worker that they are in the danger zone. One of the many advantages of the system is that there are zero false alarms.

To detect vehicles and objects, SCAN~LINK offers marker tags; small, rigid, passive RFID tags that can be applied to anything that you wish to detect. Again, there are no false alarms with this type of system as the application of tags controls what the system will detect. The advantage of a Passive RFID System is that no batteries or charging are required; even the Apparel. What makes the Armour System unique is that any vehicle equipped with an Armour Antenna will detect any ground worker, on any job site, wearing an Armour equipped Safety Vest and Hard Hat.

The SCAN~LINK Armour System™ is used globally in the Oil & Gas, Construction, Mining, Waste and Forestry Industries to mitigate human and vehicle interaction. The standard system can operate in temperatures from -20°C to +85°C and a cold temperature version tested to operate at -40°C is also available.

Workplace safety continues to rise in importance for global CEOs across industries – and rightfully so. After all, an organization’s strategy and implementation of workplace safety programs directly affects its reputation, profitability and ability to attract and retain talent. Ineffective safety programs can also lead to severe repercussions for those responsible for protecting workers.

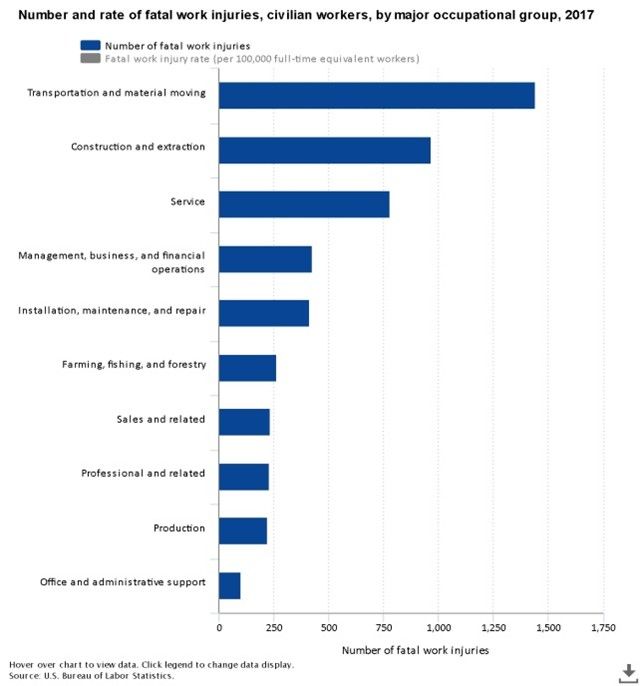

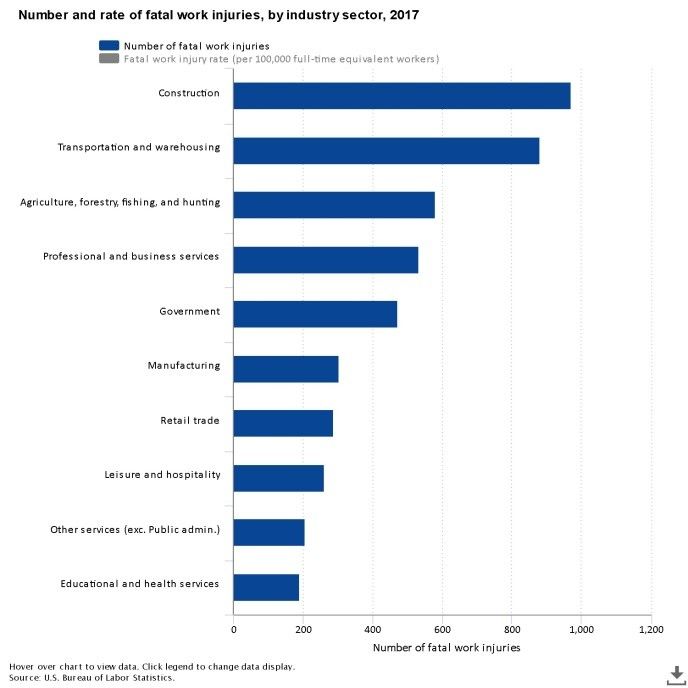

According to a 2017 US Bureau of Labor Statistics report, there were 971 Fatal Injuries in the Construction Industry alone and 1,443 Fatal Work Injuries of Civilian workers. With the various technologies available, this is an unreasonably high number.

While it can take time to implement new processes, making smart safety a reality can generally be accomplished in three steps: data acquisition and assessment, the identification of risk segments and the development of a predictive model and scoring system.

By effectively implementing advanced data analytic strategies, companies can do more than realize clear financial benefits through increased productivity, reduced litigation and sanctions, and the ability to focus limited dollars on the most effective interventions. More critically, organizations can reduce the human cost of safety by cutting the number and severity of workplace incidents.

The SCAN~LINK Armour System™ has Data capabilities which are user friendly and easy to analyze. The system collects and stores granular data such as; date, time, location and apparel type which can be allocated to a particular person. The SCAN~LINK HMI applications interface delivers HMI telemetry, geofencing, automated dashboards and event reporting, real-time alerts, and scalable data warehousing to enable input into enterprise AI machine learning solutions.

The SCAN~LINK HMI applications allows a company to analyze all of the data on their worksites for near-miss incidents and evaluate the collected data relevant to safety. From this evaluation an informed analysis will lead to more focused safety training, greater safety strategies and lower Human-Machine incidents. It will expand the view of safety beyond the employee – safety interventions have been historically employee-focused. Data can empower safety strategies with a broader focus on machinery, process and the general working environment.

[1] Deloitte – https://www2.deloitte.com/content/dam/Deloitte/ca/Documents/Analytics/ca-en-analytics-workplace-safety-analytics.pdf

²U.S. Bureau of Labor Statistics

³U.S. Bureau of Labor Statistics

[4] Deloitte - https://www2.deloitte.com/content/dam/Deloitte/ca/Documents/Analytics/ca-en-analytics-workplace-safety-analytics.pdf

[5] Deloitte - https://www2.deloitte.com/content/dam/Deloitte/ca/Documents/Analytics/ca-en-analytics-workplace-safety-analytics.pdf (Del)